The increase in demand in nonwovens for the production of medical, hygiene and personal care products has led to further growth in the sector. In addition to this increase in demand and the development of new technologies on its solutions, Trascar, a leader in the supply of systems for the handling and packaging of non-woven rolls, is also further consolidating its presence in the sector.

In 2021 there are several non-woven rolls handling and packaging systems to be delivered all over the world: the Trascar solutions will be installed both for new production lines and for existing lines, automating the processes currently carried out manually (elimination of the human intervention) or to reduce waste and eliminate the risk of material contamination that is increasingly required today (zero contamination compliant).

The new solutions will be installed to handle and pack non-woven rolls of different types (spunbond and spunlace) coming out of slitters up to widths of 5.5 meters, guaranteed quality and repeatability of the packaging even in the presence of high volumes of material (slitters with speed up to 2.000m/min and machine width of 5.5m). The new deliveries in Asia (China and India), in the USA and Europe consolidate the presence of Trascar in the different continents and with Companies increasingly looking for high performance and final product quality.

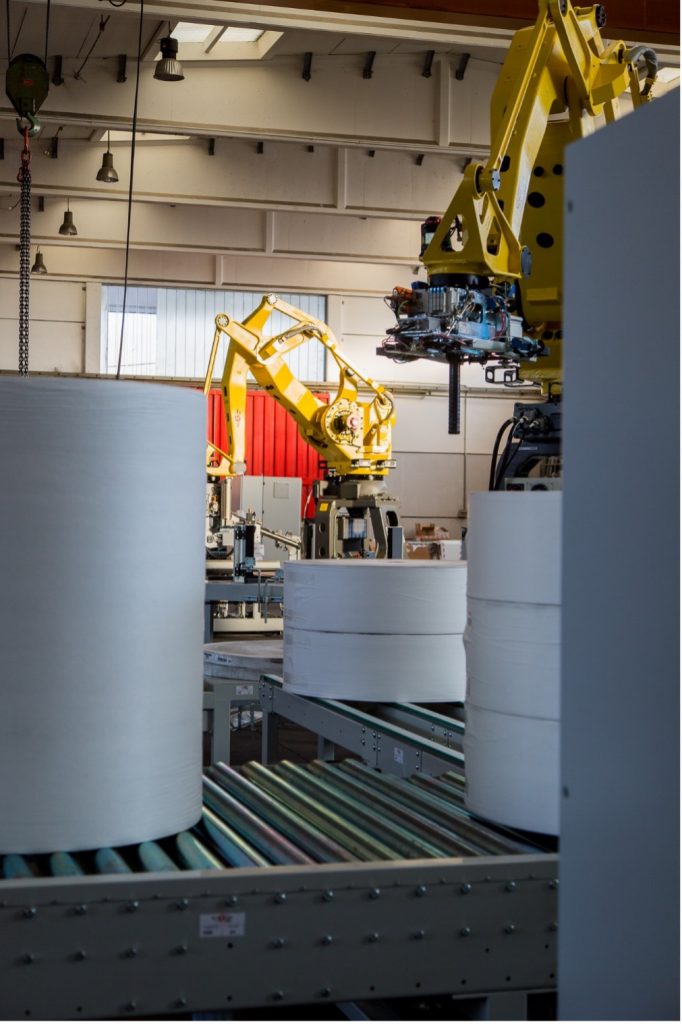

A fully automatic and centralized handling and packaging system of the latest generation will also be installed to serve different high-performance slitters: the solutions offered by Trascar are also modular and allow quick installation and commissioning. It is a multi-robot solution that allows Customers to manage up to 700 reels/hour.

The development of a new automatic labelling system also allows to obtain a rapid and precise process with labels on each slitted reel (external or on the core) and/or on the bundle, interfacing with the Customer’s ERP to report the information necessary for allow the complete traceability of the single reel or bundle to the end user.

Thanks to these new installations, Trascar Customers will be able to benefit from less space required for handling and packaging activities, will have the ability to manage work peaks without hiring additional personnel and will no longer have bottlenecks between the production line and the reels packaging operations.

In addition to all these points, with Trascar’s after-sales service the Customer is accompanied throughout the useful life of the system through the remote connection tools and ad-hoc services solutions (preventive maintenance, remote helpdesk, …).